Henry Vogt Henry Vogt was born in Louisville, KY in 1856 to a family of poor German immigrants. In 1880, he opened a small machine shop on Main Street in Louisville. In 1885, a boiler shop and foundry were added to the small machine shop for the manufacture of new products to make “artificial” ice - the Absorption Refrigeration and Ice Making Machine.

Today Vogt Valves supports a worldwide network of distributors and customers with access to the world’s largest capability for manufacturing of forged steel valves. Meeting the needs of the following industries: chemical, petrochemical, process and petroleum industries.

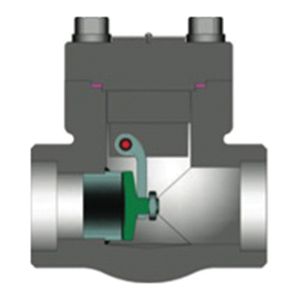

Pipeline Gate Valves:

Vogt offers Pipeline Gate Valves for Oil & gas field services, drilling, transportation, distribution and storage. Cast or Fabricated design are available up to 48’’. Forged version are supplied for high pressure services. Offered in a wide variety of choices of body and trim materials including Low Temperature Carbon, Stainless and Nickel Alloys. Through Conduit Valves can be supplied to API6D or API6A.

Available configurations include:

- Slab Type (cast and forged)

- Expanding Gate (cast and forged)

- Pipeline Slab Gate (fabricated)

- Pipeline Expanding Gate (fabricated)

All valves can be supplied or actuator operated. Vogt also offers a complete range of Floating and Trunnion Mounted Ball valves in forged and cast materials. Choices include: soft and metal seated trims. Material include Low Temperature Carbon steels, Stainless, Nickle Aluminum Bronze, Nickel Alloys and Exotic material only from US and European sources. All valves are certified to API641 for low Fugitive Emission.

Other configurations include:

- API608 Side Entry Floating

- API608 Top Entry Floating

- API6D Side Entry Trunnion

- API6D Top Entry Trunnion

- API6D Fully Welded Trunnion

- API6A Trunnion

- Modular valves

Vogt offers a full range of Triple Offset valves for the Oil & Gas and Process industry.